Design Guidelines PCB-A

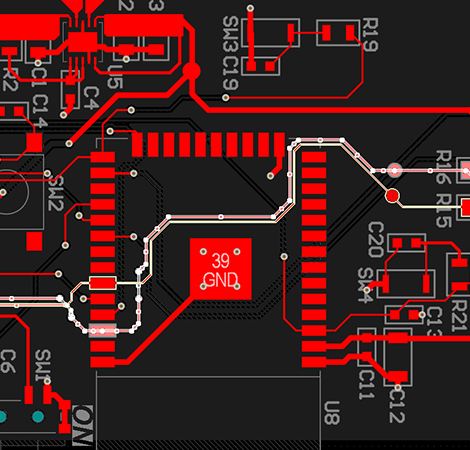

Printed circuit boards (PCBs) are fundamental to virtually all modern electronic devices. Therefore, when assembling a PCB or collaborating with our team on its assembly, it is vital to share a common understanding of best practices, terminology, and procedures.

Although the industry is constantly evolving, many key terms and practices remain unstandardized. For these, our team has prepared clear explanations to ensure everyone is aligned before moving forward with more detailed discussions.

The PCB Power team has refined these guidelines through years of experience, careful observation, and feedback. We believe following them will help reduce errors, shorten lead times, and lower costs throughout the PCB assembly process.

Data Requirements

The assembly process is dependent on two key datasets:

Bill of Materials (BOM) or Parts List:

This list contains every component involved in the manufacturing and assembly of the PCB. Typically, it includes a file that details each part’s description, Manufacturer’s Part Number (MPN), Supplier’s Part Number (SPN), and Reference Designators such as R1, C2, IC3, and so on. The list should be as detailed and complete as possible, covering all components required for assembling the PCB.

Component Placement List (CPL):

As the name suggests, this file directs the PCB Assembly process by dictating the precise position, degree of rotation, and the designated side of the board, along with the reference designator that has to be populated. The file is frequently called the Pick & Place File, Centroid File, XY File, and Position File.

Want to avoid common exceptions while ordering PCBs?

Designing on Kicad?

Click Here For Guidelines Data Requirements

The assembly process is dependent on two key datasets:

Bill of Materials (BOM) or Parts List:

This list contains every component involved in the manufacturing and assembly of the PCB. Typically, it includes a file that details each part’s description, Manufacturer’s Part Number (MPN), Supplier’s Part Number (SPN), and Reference Designators such as R1, C2, IC3, and so on. The list should be as detailed and complete as possible, covering all components required for assembling the PCB.

Component Placement List (CPL):

As the name suggests, this file directs the PCB Assembly process by dictating the precise position, degree of rotation, and the designated side of the board, along with the reference designator that has to be populated. The file is frequently called the Pick & Place File, Centroid File, XY File, and Position File.

Want to avoid common exceptions while ordering PCBs?

Designing on Kicad?

Click Here For Guidelines